Primary Air Incinerator Fans

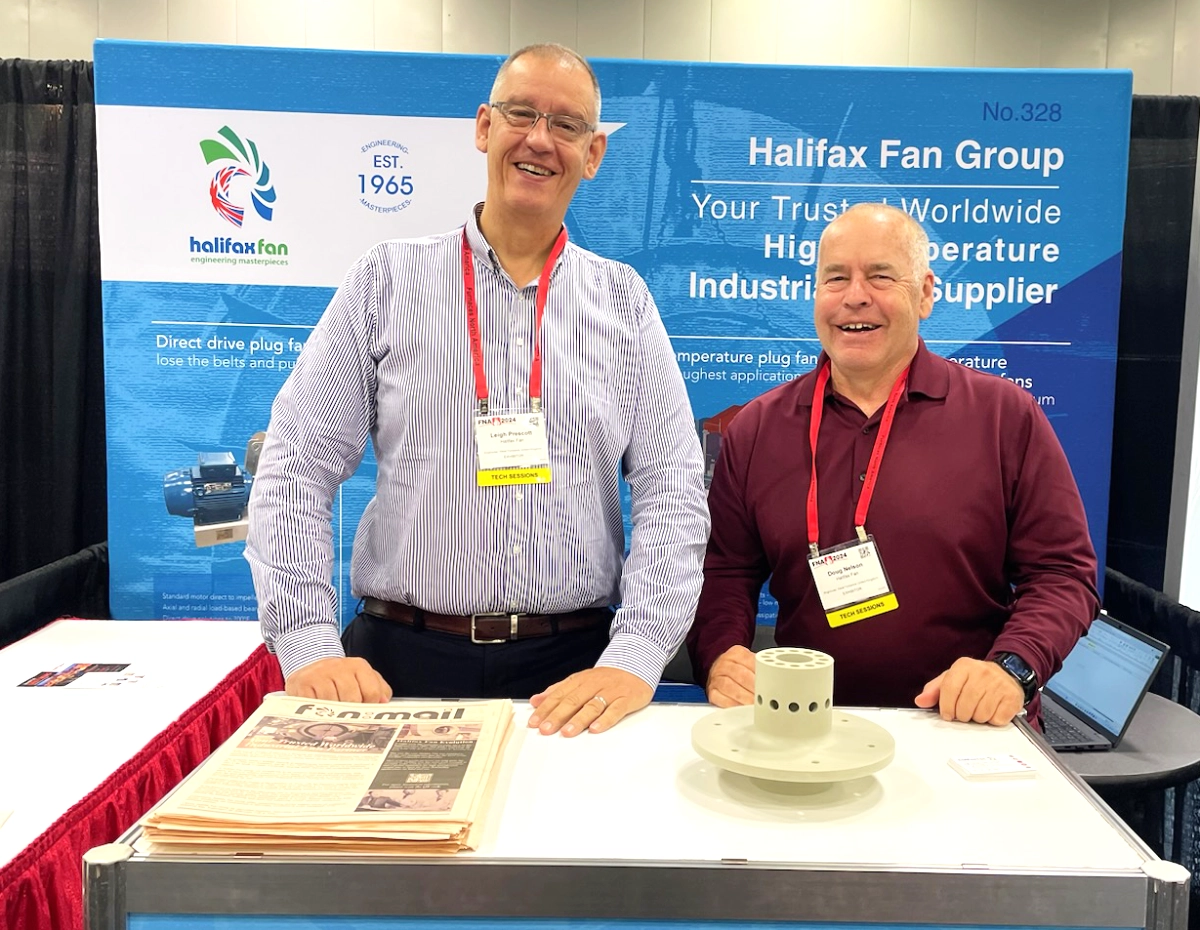

Serving our Canadian customer, with Halifax Fan Group providing support in the USA, Asia, and locally.

Serving our Canadian customer, with Halifax Fan Group providing support in the USA, Asia, and locally.

It’s been a busy and exciting week for exhibitions worldwide. We wrapped up by participating in the Eerduosi Chemical Show in China.

With our fans built to API, ATEX, IECEx, and CCCEx standards from our factories in China, along with the support of our service teams across Asia, we have established ourselves as a trusted supplier in this industry.

Bringing European and asian high temperature fan technology to the USA market!

We have IECEx and CCCEx certifications, as well as the ability to manufacture ATEX-certified fans.

There is a mixture of 45 and 42” plug fans fitted with pressure sensors.

Our team this week are at THERMPROCESS in Shanghai, we have two factories in China and a full team grown over the last 18 years.

They will operate as combustion blowers for incinerators.

The owner specified AMCA ARR.4 structure due to compact installation area.

Had a fantastic first day at the Environmental Services & Solutions Expo.

Cleaning the environment, this 600 HP fan in our Syracuse factory is one of several for a large scrubbing system. This fan and several others in the process will be