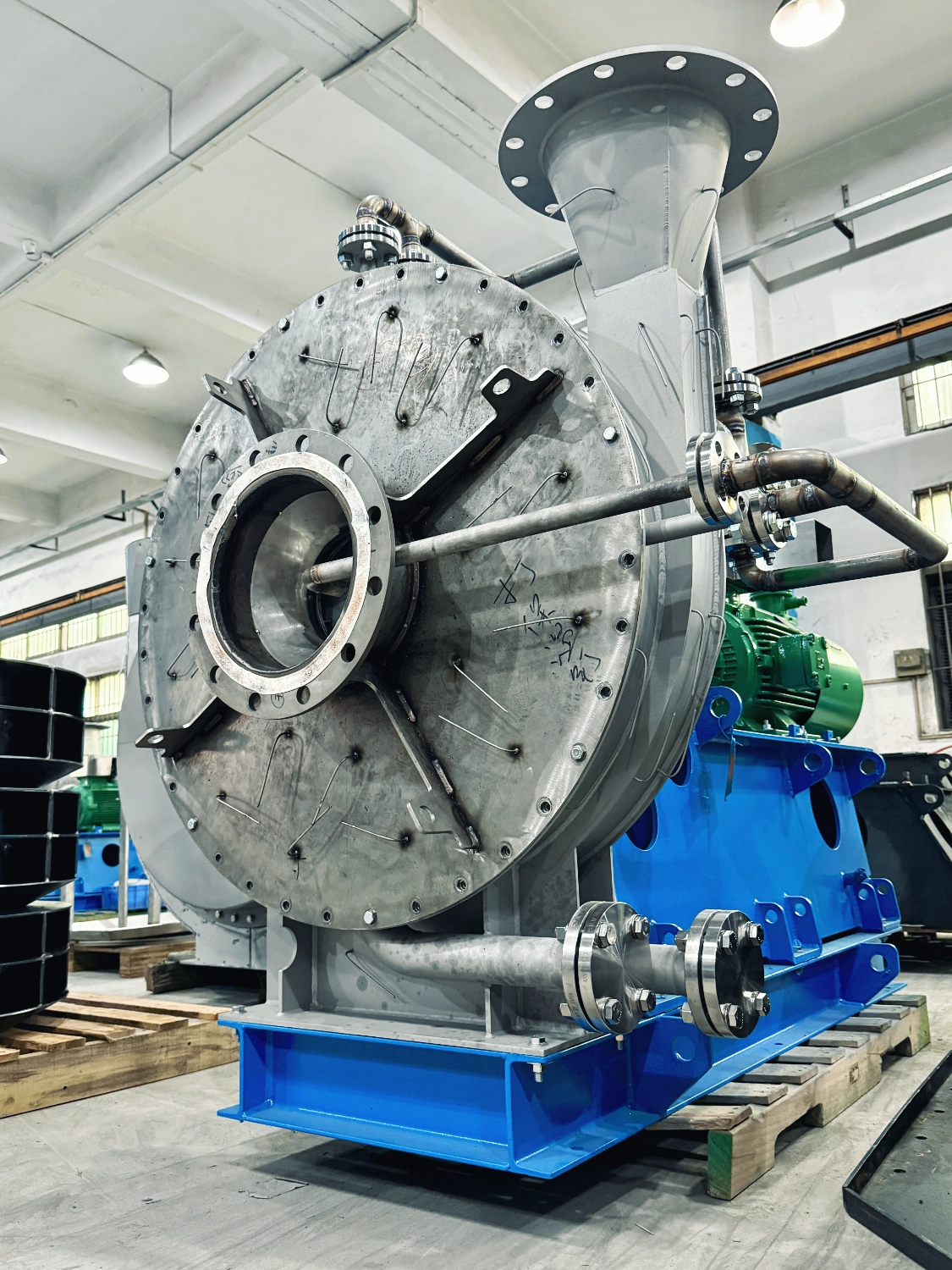

Energy efficient chemical drying fan

A performance test led to replacing the fan with a 23% more efficient model.

A performance test led to replacing the fan with a 23% more efficient model.

Fan Constructor™ brings speed and precision and allows us to instantly generate accurate quotes and 3D designs.

We have IECEx at both Chinese factories, which is gaining popularity in Asia and Australia.

With our fans, you can expect precision, accuracy, and unmatched expertise.

At Halifax Fan Group, we work side by side for many days and hours.

Lyndon Tyas has joined Halifax Fan Group in the U.K as our Production Manager.

The exhibition is open, and we are here to tell you all about our lovely fans.

We are proud to show our latest shipment from our USA manufacturing plant: high efficiency 53” backward curved,

Fan Constructor™ allows our team to instantly generate accurate quotes and 3D designs, bringing unmatched speed and precision to every project.