We Love Exporting! Our Stainless Steel Fans Headed to the USA

The fans are fully gas tested and designed to meet 11Bar and have extensive run, vibration and performance tests prior to shipping.

The fans are fully gas tested and designed to meet 11Bar and have extensive run, vibration and performance tests prior to shipping.

The customer had a more efficient and maintenance friendly solution – saving them lots of dough.

A super chocolate biscuit factory in the U.K contacted us about a problem they were having with some old fans which kept breaking down.

This Open Radial Bladed fan will be used to convey tobacco dust and silica. The casing and impeller are constructed from a special martensitic abrasion

The fans are designed to ATEX directive Zone 1, 2G IIB T4 and manufactured from 304SS.

At Halifax Fan, our dedication to training, innovation, and global collaboration is driving us towards a future where industrial fan issues are swiftly identified, analysed, and resolved, delivering unmatched value to our clients.

Our testing facility is equipped with several variable speed drives and features a remote monitoring station on the outside of the main test bay.

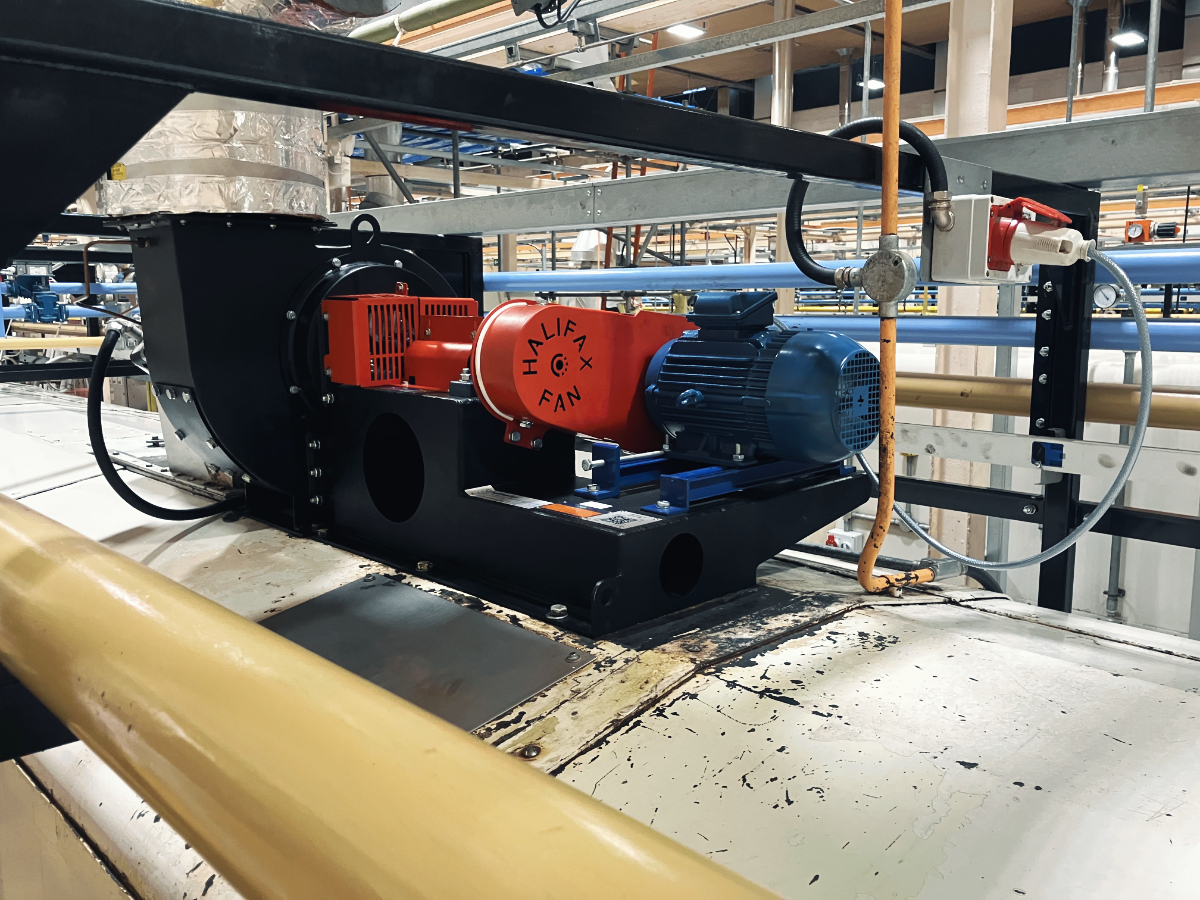

A clad fan designed for coping with the UK winter serves as an exhaust fan for a plasterboard drying oven.

Industrial fans need to cope with extreme levels of humidity, temperature and corrosive environments. To do this Halifax apply high performance protective coatings. Using the latest high performance protective coatings requires specific coating film thicknesses at the application stage.

Getting our ‘ducts in a row’ ok they are not ducts, they are bifurcated fans (BIF)