Halifax Fan UK Enhances Coating Efficiency with Spraytrain

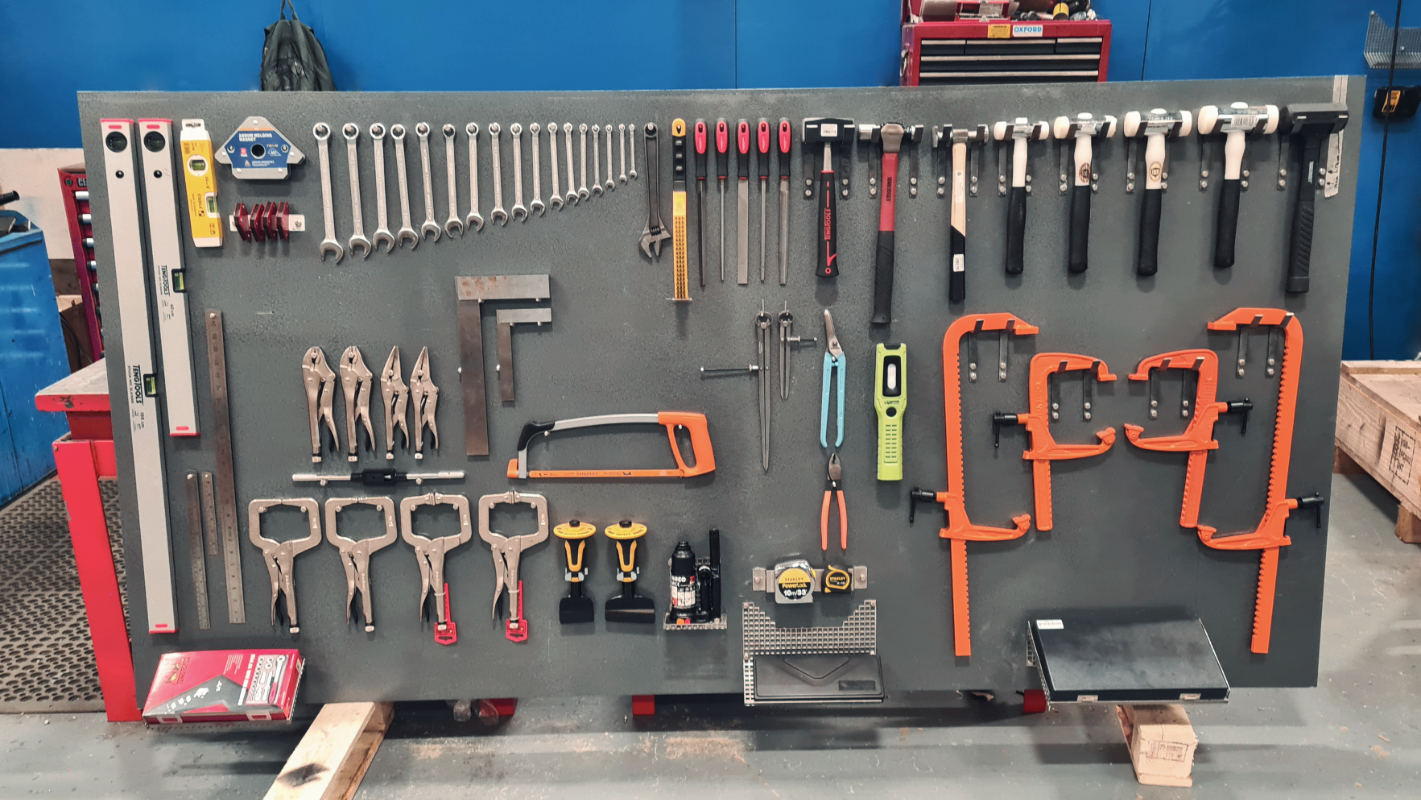

Industrial fans need to cope with extreme levels of humidity, temperature and corrosive environments. To do this Halifax apply high performance protective coatings. Using the latest high performance protective coatings requires specific coating film thicknesses at the application stage.